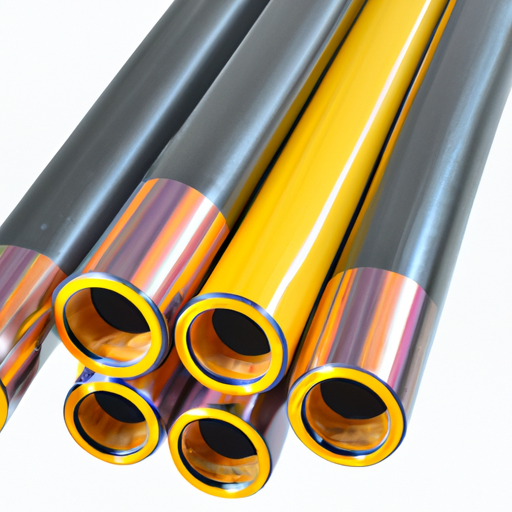

Diesel-resistant heat shrinkage tubes are an essential component in various industries, especially in automotive and aerospace applications where exposure to diesel fuel is common. These tubes are designed to provide protection against heat, chemicals, and abrasion, making them ideal for use in harsh environments.

One of the most important product standards for diesel-resistant heat shrinkage tubes is the material used in their construction. These tubes are typically made from a specialized polymer material that is resistant to diesel fuel, as well as other chemicals and solvents. The material must be able to withstand high temperatures and provide excellent insulation properties to protect the wires or cables inside.

In addition to the material, the thickness of the heat shrinkage tube is also a critical factor in determining its performance. Thicker tubes provide better protection against heat and abrasion, while thinner tubes are more flexible and easier to install. Manufacturers must ensure that the thickness of the tube meets the required standards to provide the necessary level of protection.

Another important product standard for diesel-resistant heat shrinkage tubes is their resistance to diesel fuel. These tubes must be able to withstand exposure to diesel fuel without degrading or losing their protective properties. This requires thorough testing and certification to ensure that the tubes meet the necessary standards for resistance to diesel fuel.

Furthermore, the shrinkage ratio of the tube is also an essential product standard to consider. The shrinkage ratio determines how much the tube will shrink when exposed to heat, allowing it to conform tightly to the wires or cables inside. Manufacturers must ensure that the shrinkage ratio of the tube meets the required standards to provide a secure and reliable seal.

In addition to these key product standards, manufacturers must also consider other factors such as color coding, UV resistance, and flame retardancy when designing diesel-resistant heat shrinkage tubes. These additional features help to enhance the performance and durability of the tubes, making them suitable for a wide range of applications.

Overall, product standards for diesel-resistant heat shrinkage tubes are essential to ensure the quality and reliability of these critical components. By meeting these standards, manufacturers can provide customers with high-quality tubes that offer superior protection against heat, chemicals, and abrasion, making them an essential solution for demanding applications in various industries.